Search

The first ASME BPE Meeting was held on May 15, 2023 in New Orleans, a city in the Southern United States. As a member of ASME BPE Committee and representative of the Greater China, Mr. Gu Zhenghui (Vice President of Morimatsu LifeSciences) attended the meeting and exchanged with international peers on the revision of ASME BPE 2022 and future trends of biopharmaceutical facilities during the three-day meeting.

Mutual Empowerment of Morimatsu & ASME BPE

ASME BPE is the worldwide Standard on how to design and build equipment and systems used in the production of biopharmaceuticals. It is published by American Society of Mechanical Engineers (ASME) and resulted from industry requests for standardization arising from rapid development, aiming to set leading standards for designs of biopharmaceutical manufacturing systems. It incorporates current best-practices in the industry, and provides comprehensive, detailed, and rigorous technical requirements and methodologies for the design, materials, manufacturing, inspection, cleaning and sanitizing, testing, and certification of stainless steel and disposable systems.

(ASME BPE 2022 Edition)

Members of the ASME BPE Committee are from different sectors of the pharmaceutical industry. Since joining the ASME BPE Committee in 2010, Morimatsu has been continuously working on the development of ASME BPE, and promoting its presence in the Greater China, to facilitate the manufacturing of pharmaceutical production systems and facilities and improve product quality for end users, thus enhancing everyone's lives and advancing the development of the industry.

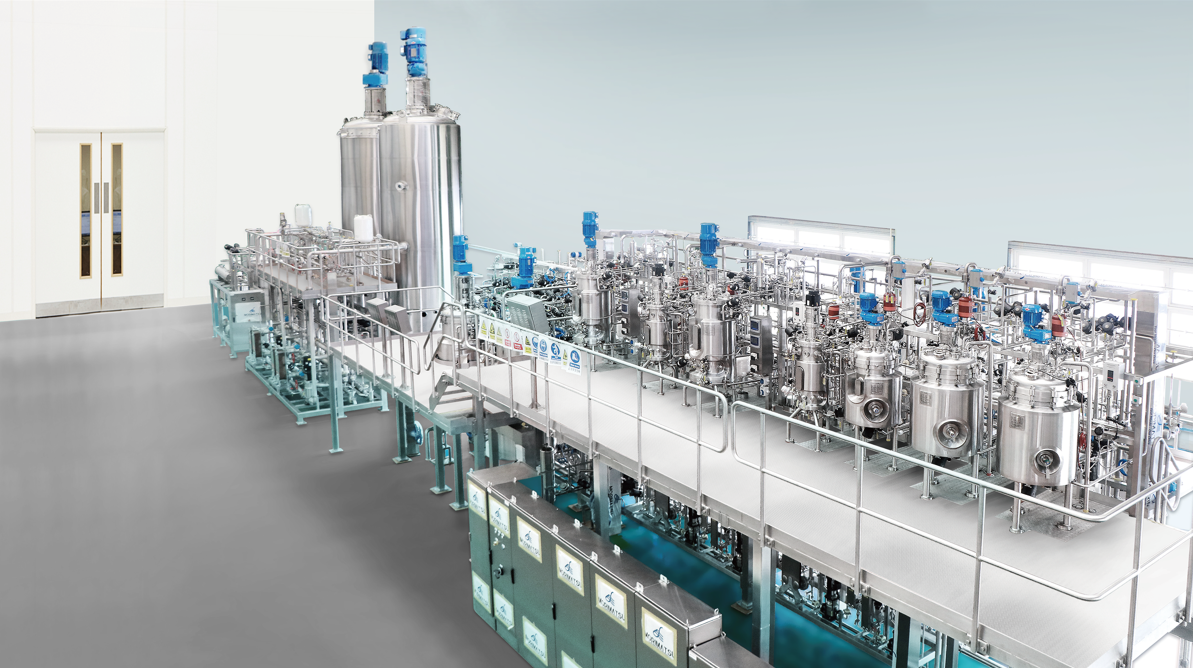

Similarly, ASME BPE has been built into the entire lifecycle of quality management system delivered by Morimatsu, covering design, construction, monitoring and maintenance. Morimatsu has created a technology platform for digital design and automated manufacturing, and strictly adhered to GMP. By taking the lead in upgrading locally-produced equipment to dock with international standards, Morimatsu aims to provide end users with reliable, cleanable, sterile and stable products, and safeguard the quality and quantity of drugs produced. The development of ASME BPE has also witnessed Morimatsu's dedication and growth in the field of life science and technology. Since the delivery of its first sanitary container in 1998, Morimatsu has successfully shipped core process systems globally.

In 2022, led by China Association for Pharmaceutical Equipment, Morimatsu took part in the development of "ASME BPE Introduction and Interpretation Compendium" to provide readers in China with an in-depth study and understanding of the Standards.

Core elements of the meeting

The meeting discussed a wide range of topics, and examined in detail the following aspects of the pending release of the Standards 2024 edition.

Definition of closed systems

Closed systems have always been a hot topic in process system design and clean plant design concepts since its introduction in BPE 2019. However, there is a significant bias in users' understanding of what a closed system is in daily use. A clear definition of closed systems is particularly important as closed process systems allow for plant designs with less cleaning requirements. ASME BPE led and coordinated with Biophorum and ISPE based in the United States to standardize the definition of a closed system, thereby enabling unified concepts and standards in terms of owners, system designers, and manufacturers.

Increase in the scope of ASME BPE certification

The current ASME BPE certification is only for metal tubing and fittings. The CR Committee is discussing the future extension of the scope of certification, with initial plans to add the certification of metal valves (excluding non-metallic fittings) around 2024. There are also discussions about extending the scope of container certification, but no actual certification acts will come into practice before 2026.

Flatness tolerance requirements for sealing surfaces of metallic flat connectors

All dimensional tolerances in the current Standards are defined as machining tolerances for flat connector suppliers, which have no relation to post-weld dimensional tolerances, and, again, there is a lack of harmonized post-weld dimensional tolerances across the industry. The DT Committee is discussing the development of post-weld flat joint dimensional tolerances, expecting to develop a harmonized acceptance standard for post-weld dimensional tolerances.

Design, Manufacturing and Acceptance Standards for Clamps

Clamps play a critical role in the history of static sealing systems. However, clamp providers have always designed and manufactured their own sizes and forms of clamps, failing to be standardized. The DT Committee is comparing the design philosophies and programs of major clamp providers, and plans to develop a clamp design standard to ensure that each supplier designs and manufactures clamps that meet the industry requirements for pressurized parts.

Definition and Selection of Riboflavin

The experimental method of sprayball is gaining public acceptance, and a variety of types and mixes of riboflavin have emerged in the industry. Riboflavins and the temperature of their solutions have a significant effect on their ease of cleaning, resulting in a fact that the sprayball water jet cannot wash the riboflavin away though it has covered the surface. The SD Committee has attempted to define riboflavin components in the Standards, thereby harmonizing the understanding of all participants.

In the future, Morimatsu will continue to fulfill its responsibilities and work together with ASME to drive the biopharmaceutical industry forward!

About Morimatsu LifeSciences

Morimatsu LifeSciences is a subsidiary of Morimatsu International Holdings Limited (Morimatsu International, stock code: 2155.HK), covering pharmaceutical, biopharmaceutical, FMCG, cosmetics, electronic chemicals and other industries, provides clients with "core equipment/Machinery + Value added + digitalized intelligence overall Plant Solutions and Service" (" MVP Solutions & Service"), mainly including Shanghai Morimatsu Pharmaceutical Equipment Engineering Co., LTD., Morimatsu (Suzhou) LifeSciences Co., LTD., Shanghai Morimatsu Biotechnology Co., LTD., Shanghai Mori-Biounion Technology Co.,Ltd. and Pharmadule Morimatsu AB., Morimatsu Pharmadule (Singapore) Private Limited as well as their subsidiaries. Morimatsu LifeSciences is focusing on the research and development, manufacturing, and sales of products in related fields.

From the start in Japan, Morimatsu has grown and today is a diversified multinational corporation with vast experience and professional know-how in fields of process engineering equipment as well as modular engineering solutions. Our company has established long-term collaboration relationships with numerous well-known global corporations. We have companies in Sweden, Italy, US, India, Singapore, Malaysia, together with the large scale operation and manufacturing facilities in Asia. So far, Morimatsu has delivered projects to more than 40 countries/regions in the world, established an excellent industrial reputation in the process.

Forward-Looking Statements

The information in this press release may include some forward-looking statements. Such statements are essentially susceptible to considerable risks and uncertainties. The use of "predicted", "believed", "forecast", "planned" and/or other similar words/phrases in all statements related to our company is to indicate that the statements are forward-looking ones. Our Company undertakes no obligation to constantly revise such predicted statements.

Forward-looking statements are based on our Company management's current perspectives, assumptions, expectations, estimations, predictions and understanding of future affairs at the time of the making of such statements. Such statements are not guarantees of future development and are susceptible to the impact of risks, uncertainties and other factors; some are beyond the control of our Company and unpredictable. Subject to the influence of future changes and development in our business, competition environment, political, economic, legal and social conditions, the actual outcomes may differ significantly from the information contained in the forward-looking statements.